HARD CARBON FELT

Application and features:

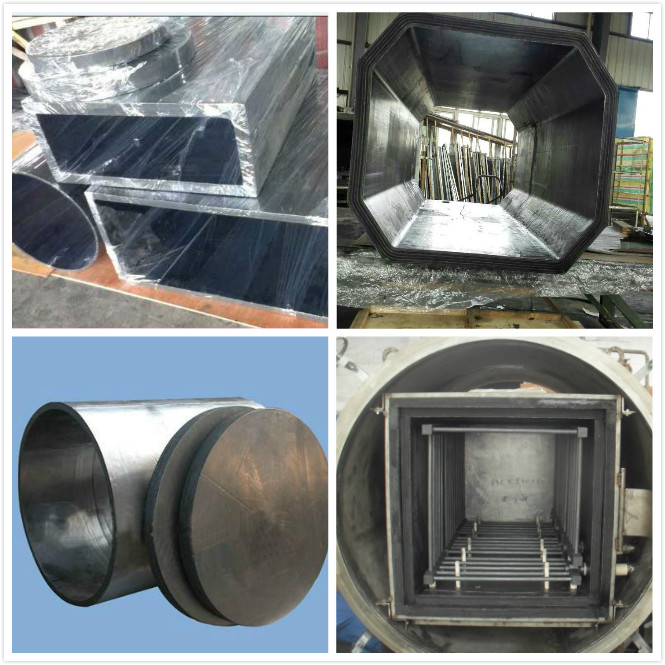

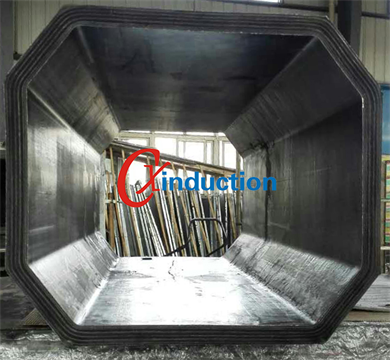

The hard graphite felt is a composite which choose the PAN-based graphite felt as mixture material. The felt is achieved by carbonization and graphitization process with the special binding agent, after its primary graphitizing at over 2000℃. It has the good rigidity and self-support, less dense, no short fiber shedding, low thermal conductivity coefficient and can work under the temperature of 3200℃. It applies to a various of furnace such as high-pressure gas quenching furnace, pressure sintering furnace, poly-crystal casting furnace, single-crystal grown furnace (sapphire grown furnace) etc., especially for the high temperature furnace with strict requirement by atmosphere due to its most important character of supper purity (<200ppm) and extremely high temperature resistant. And it can shape to be plate, disc, cylindrical etc. with long working life and convenient installation and removal.

Properties:

| Volume weight g/cm3) | Themal inductivity coefficient (w/m k) | Specific heat (J/gk) |

| 0.23~0.25 |

1500℃ 0.15 2000℃ 0.25 |

0.91 |

| Compressive strength (M/Pa) | Bending strength(M/Pa) | carbon content(w%) |

| ( 30mm thickness)≥0.4 | 30mm thickness) ≥0.7 | ≥97 |

| Ash content (w%) | Maximum working temperature | |

| 0.6-0.9 |

Air(℃)300 Vacuum(℃)1800 Shielding gas(℃)2800 |

Package: Wooden case or carton.

Cautions of use: When the working temperature is over 300℃, it should be working in shielding or inert gas. It can not be under pressure and should be protected against moisture during transportation and store. It can be cut into any geometrical shape. Please wear the protective clothing when cutting.